Specialty Manufacturing

Contract Manufacturing — Managed End to End

From complex prototypes to tightly controlled production runs, Geospace Technologies delivers contract manufacturing services built for projects where quality, cost, and accountability matter equally. We combine deep in-house manufacturing expertise with disciplined program oversight, giving you a single, trusted partner who manages every detail from concept to completion.

manufacturing for simple & complex applications

Contract manufacturing isn’t just about having the right machines — It’s about knowing how to apply them. Our teams work closely with customers to evaluate each project’s technical requirements, tolerances, materials, and cost targets to determine the most efficient path to production.

Injection Molding

Geospace offers injection molding services with over 35 machines and multi-shift availability. We work with a variety of materials, including polyethylene, polypropylene, nylons, and custom compounded plastics, including glass, metal, and mineral-filled options. Our in-house tooling design and fabrication ensures quality, and we can accommodate shot sizes up to 90oz. Through our partnerships with leading resin manufacturers, we can offer solutions for complex applications.

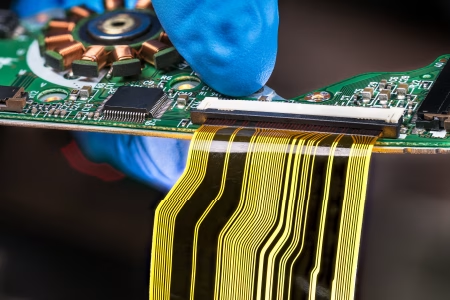

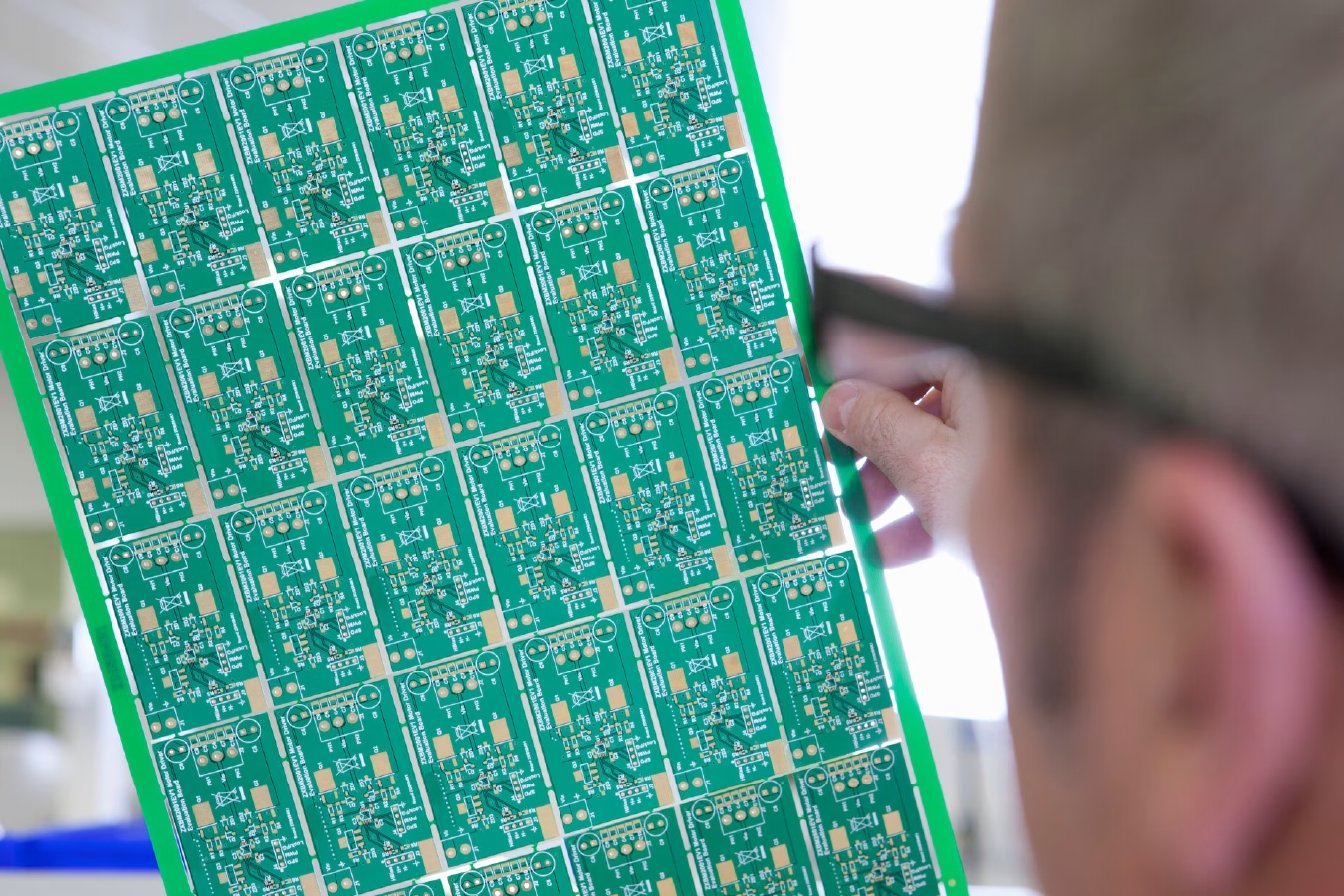

Electronic Manufacturing Services

Our electronic manufacturing services include microelectronics with full clean room capabilities (Class 10K and 100K), along with die-attach, wire bonding, and encapsulation. We produce a wide array of cable and wire harnesses, from simple crimp and poke to complex designs, with 100% point-to-point testing. Our PCB assembly services range from prototyping to high-volume manufacturing, always maintaining top-tier capabilities and uncompromising standards. Geospace also provides comprehensive system/box build services, including panel assembly, wiring, component mounting, system integration, cabling, and board assembly.

precision machining

Geospace provides high-quality contract machining supported by advanced equipment and in-house expertise. With more than 20 machines, including Swiss multi-tasking lathes, four and five-axis mills, and high-efficiency saws, we handle complex parts with demanding tolerances. Our custom tooling and climate-controlled inspection lab ensure consistent accuracy across materials from polymers to titanium. Integrated automation and responsive design support help streamline production and reduce lead times — delivering reliable results, fast.

Quality Assurance

Geospace integrates full plastics, PCB assembly, and cabling capabilities under one roof to ensure the highest quality from the start. By controlling the supply chain and with in-house tooling design and fabrication, we ensure a stable and repeatable process.

Geospace is certified to the latest revisions of ISO 9001, 14001, 13485, 45001, and AS9100 standards, as well as eX/ATEX and ITAR-compliant. We also maintain environmentally sound working conditions across all of our facilities.

Injection Molding in Houston, Texas with Geospace Technologies

Injection molding is a key manufacturing process that offers precision and efficiency for the...

3 Common Types of Flexible PCB Materials and Their Uses

Flexible PCBs have revolutionized the landscape of modern electronics, offering versatility and...

PCB Testing Technology and Methods, Explained

The value of the printed circuit board (PCB) market is expected to keep growing by 5% up until...